Facts About Sand Blaster For Sale Revealed

Wiki Article

8 Simple Techniques For Sandblasting

Table of ContentsFascination About Abrasive BlastingSandblasting Can Be Fun For AnyoneThe Buzz on Dustless Blasting Near MeAll About Dustless Blasting Near MeSand Blaster For Sale - TruthsUnknown Facts About Mobile Sandblasting Near Me

Wet abrasive blowing up uses water as the liquid moving the abrasives. The water cushions the influence on the surface area, lowering the removal of sound material. One of the initial pioneers of the damp unpleasant process was Norman Ashworth who located the advantages of making use of a damp process as a strong choice to dry blowing up.

Lowered impregnation of blowing up material right into the surface area, dirt reduction and also the removal of static cling can result in a spick-and-span surface area - abrasive blasting. Damp blasting of moderate steel will lead to prompt or 'flash' rust of the blown up steel substrate as a result of the existence of water. The absence of surface recontamination likewise allows the use of solitary devices for multiple blasting operationse.

The 6-Second Trick For Dustless Blasting Near Me

A variant of wet blowing up is vapor blasting (or vapour blasting; U.K.). In this procedure pressurized air is included to the water in the nozzle creating a high rate haze, called "vapor". This process is even milder than wet blowing up, permitting mating surfaces to be cleaned up while maintaining their capacity to mate.Blending fragments with water significantly reduces dust. Bead blasting is the process of getting rid of surface down payments by using great glass grains at a high stress without damaging the surface.

In getting rid of paint for car body job, bead blasting is preferred over sand blasting, as sand blowing up tends to develop a higher surface account than grain blasting. Bead blasting is often made use of in producing a consistent surface area finish on machined components.

What Does Shot Blasting Near Me Do?

The very first blast wheel was patented by Wheelabrator in 1932. Hydro blowing up is not a type of unpleasant blowing up as no abrasive media is utilized. Hydro-blasting, commonly known as water blasting, is commonly utilized because it typically calls for only one operator.This technique is perfect for cleaning inner and external surface areas due to the fact that the driver is normally able to send out the stream of water into locations that are challenging to get to making use of other methods. One more benefit of hydro-blasting is the capacity to recapture as well as recycle the water, reducing waste and mitigating ecological influence.

Greater stress are commonly needed. The most typical micro-abrasive blasting systems are business bench-mounted systems being composed of a power supply and mixer, exhaust hood, nozzle, and gas supply. The nozzle can be hand-held or fixture placed for automated procedure. Either the nozzle or component can be relocated in automated procedure.

Excitement About Abrasive Blasting

Automated blowing up is often just a step in a larger automated treatment, normally including visit our website other surface Extra resources therapies such as preparation and coating applications.The air compressor supplies a large quantity of high pressure air to a single or numerous "blast pots". Blast pots are pressurized, tank-like containers, full of abrasive product, made use of to enable an adjustable amount of blasting grit into the main blowing up line. The variety of blast pots is dictated by the volume of air the compressor can provide.

Damp blasting is often made use of in applications where the very little dust generation is preferred. Portable applications might or may not reuse the rough.

The Greatest Guide To Sand Blasting Sand

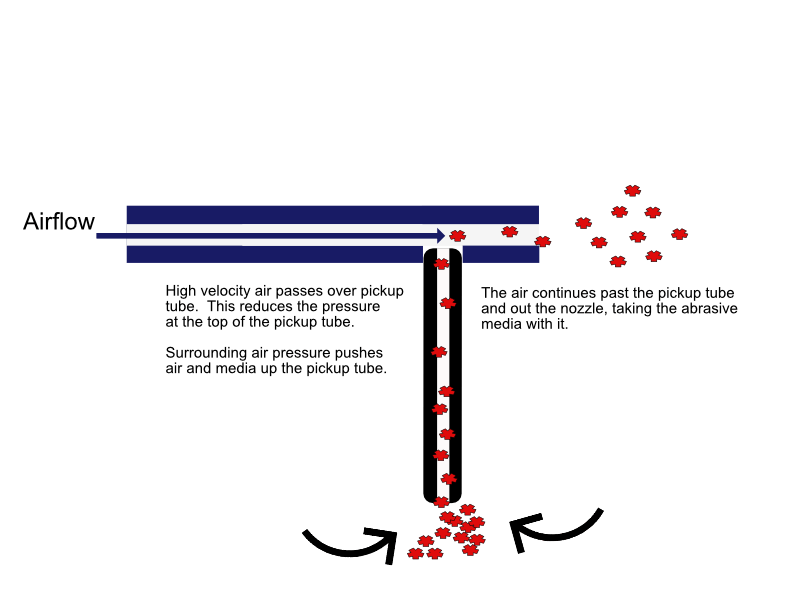

There are three systems generally made use of in a blast cabinet. 2, siphon and also pressure, are dry as well as one is damp: A siphon blast system (suction blast system) uses the compressed air to develop vacuum cleaner in a chamber (called the blast weapon). The adverse stress pulls unpleasant right into the blast weapon where the compressed air guides the abrasive via a blast nozzle.

Nozzles are available in a range of forms, dimensions, and materials. Tungsten carbide is the liner product usually utilized for mineral abrasives. Silicon carbide as well as boron carbide nozzles are a lot more wear resistant and also are frequently used with harder abrasives such as aluminium oxide. Cost-effective abrasive blasting systems and also smaller closets use ceramic nozzles.

A Biased View of Mobile Sandblasting Near Me

The vessel is pressurized to the same pressure as the blast hose affixed to the bottom of the pressure vessel. The abrasive is metered into the blast hose as well as shared by the compressed gas with the blast nozzle. Wet blast cabinets use a system that injects the abrasive/liquid slurry into a compressed gas stream.Report this wiki page